Butyl acetate’s story reaches back to the early days of industrial chemistry, surfacing as chemists took nature’s simple elements and pressed them into service for the modern world. Early uses saw butyl acetate in paints and coatings, with its sweet smell drifting across workshop benches and factory floors. Industrial growth after both world wars sparked demand for new materials and solvents that would keep up with an increasingly mechanized society. Chemists relied on their developing understanding of organic reactions to produce esters like butyl acetate in larger, more consistent batches. The post-war boom led to a wave of new formulations built around solvents that could do more than just dissolve. People took notice of how esters improved the look and feel of consumer products, leading manufacturers to lean heavily into research and improvement, chasing higher purity, and safer processes. With reliable large-scale production established, the chemical became a fixture in supply chains across North America, Europe, and Asia.

Every time I’ve worked with butyl acetate, its fruity odor made it stand out compared to harsher alternatives. It plays a supporting role in paints, lacquers, inks, and coatings, where it encourages quick drying and smooth finishes. It has that knack for dissolving resins and polymers without making them sticky or brittle. In labs, butyl acetate attracts attention as a mobile phase in chromatography, providing consistent results with little fuss. Its low water solubility helps keep things partitioned, so it shows up in cleaning agents and adhesives where water just won’t cut it. The flavors and fragrances sector reaches for it as a fruit essence booster in candies and perfumes, turning chemistry into something sensory and tangible.

This solvent speaks the language of organic chemistry—clear, colorless, with a boiling point hovering around 126°C, and a melting point near -78°C. Its density and refractive index fall right within the range for an ester its size. It carries a flash point between 22°C and 27°C, so storage demands respect, and it evaporates fast enough to keep work moving, but not so quickly that things get out of hand. Its relative inertness lets it mix with other common solvents like ethanol and acetone, but it keeps its distance from water, making separations straightforward. I’ve watched chemical engineers favor butyl acetate because their equipment could rely on predictable vapor pressure curves, and plant operators appreciate how it holds up in storage tanks.

Butyl acetate typically arrives with purity no less than 99%, verified with gas chromatography. Suppliers detail water content, acidity, and the presence of any side products. Labels flag UN numbers, flammability, and health hazards per the Globally Harmonized System standards. On job sites, safety data sheets are never buried—they come right out, describing handling protocols, proper PPE, and spill clearance steps. Regulators set transport restrictions and specify container requirements to minimize risks during storage and transfer, since even small spills can vaporize quickly and produce strong fumes. The routine of checking paperwork, verifying drum markings, and double-sealing containers comes from hard-earned experience with volatile organics.

The majority of butyl acetate entering the market gets produced using Fischer esterification, combining acetic acid and n-butanol over an acid catalyst, usually sulfuric acid. Chemists often use reflux, running the mixture under heat to drive the reaction as water gets continuously removed. Operators rely on distillation to purify the volatile ester, carefully controlling temperature gradients to capture the product but let heavier leftovers stay behind. In smaller operations, batch reactors and continuous flow systems both have their advocates; some swear that tweaking reagent ratios on the fly in a continuous plant squeezes out a bit more yield. The process demands attention: control the acid, watch the exotherms, monitor the clean-up, and test samples at each stage.

Butyl acetate reacts like other esters under both acid and base hydrolysis, so it breaks down into acetic acid and butanol if exposed to water and the right conditions. Manufacturers seeking tailored performance may introduce different alcohols or even tweak the acid in their esterification processes, spinning out isomers or related esters for niche solvent applications. Industrial chemists sometimes push the molecule towards transesterification, where butyl acetate can morph into other esters when exposed to alternative alcohol sources. That versatility drives innovation when industries demand specific drying rates or solubility for their products. When downstream modifications get involved, skilled chemical engineers lean into catalytic hydrogenation or halogenation to carve new solvent profiles from the butyl acetate backbone.

Butyl acetate doesn’t travel under one name. You hear it called n-butyl acetate, butyl ethanoate, or even banana oil in casual circles, a nod to both its structure and its aroma. In distributed chemical catalogs, you’ll see labeling as BAC, Fema 2221, or even with commercial house codes like "Du Pont Butyl Acetate" depending on region and supplier. Regulatory agencies track it by CAS Number 123-86-4, and customs declarations often shorten the name for quick reference. Each name springs from the context—lab work, industrial procurement, or environmental testing. It pays to know them all to avoid confusion in order forms or in transit.

Take butyl acetate safety seriously, just as much as any volatile solvent. The fumes sting eyes and throats, so ventilation makes all the difference—good fans and monitor alarms bring peace of mind. PPE isn’t a suggestion, it’s a must: gloves, splash goggles, flame-retardant clothes. Flammable liquid cabinets keep drums out of the main workspace, and spill kits stand within reach. On larger production floors, static control becomes second nature—no one wants a stray spark to start a fire. Federal and local occupational health agencies spell out exposure limits based on years of workplace research; air sampling becomes part of routine operations. Anybody moving butyl acetate through a pipeline follows strict written procedure—valve checks, pressure logs, and emergency drills happen because one missed step can mean not just lost product but direct risks to people on the ground.

Most butyl acetate I’ve run across ends up as a solvent in surface coatings, where it thins paints and adjusts their drying time for automotive, marine, and building products. Printing ink makers like it because it keeps pigments flowing without making paper curl or smudge, balancing the fast pace of modern printing presses. Adhesive formulators prefer its solvent strength for tough-to-bond vinyl and plastics, dialing in tack times and bond strength. In the flavors and fragrance trade, food-grade standards open the door for tiny additions as artificial flavor enhancers, especially in products aiming for that sweet, fruity edge. Pharmaceutical companies rely on it to purify active ingredients via extraction and crystallization, taking advantage of its selective solubility and low residue. Sometimes I’ve seen butyl acetate pop up as a cleaning agent for machinery, breaking up grease and stubborn residues. These industries depend heavily on steady quality and responsible stewardship, since even minor contamination could ripple through finished goods.

Research into butyl acetate hasn’t stood still. Green chemistry teams keep searching for bio-based routes, converting plant-derived acetic acid and bio-butanol into butyl acetate in cleaner, energy-saving processes. Novel catalysts, including reusable resin beds and solid acids, promise to cut down waste acid streams and lower operating costs. Laboratories around the world have poured hours into tweaking molecular sieves for better water removal, inching up yields bit by bit. In product formulations, chemists toy with new solvent blends to tune the evaporation profile just right for low-VOC requirements in regulatory-sensitive markets. Digital tools, from process simulation software to molecular modelling, provide new insight into mixing and separation, reducing off-spec waste before batches are ever run. For me, seeing collaboration between industry partners and university teams has been the most exciting part; each breakthrough builds on decades of shared real-world trial and error.

Anytime I’ve handled butyl acetate, the MSDS warnings about inhalation and skin contact stay clear in my memory. Animal studies show central nervous system effects and temporary respiratory harm at high doses, driving strict occupational exposure limits. Regulators refer to peer-reviewed studies showing low bioaccumulation in aquatic environments, which shapes spill containment and run-off policies. Over the last decade, more work has focused on chronic low-level effects and potential breakdown products—both in living organisms and the wider environment. In food and fragrance uses, the permitted levels run incredibly low, based on multi-year assessments from the FDA and European authorities. Training and monitoring programs help workers stay within safe exposure windows, and in my experience, no one ignores a vapor alarm after they’ve spent a shift with a headache from overexposure. Ongoing research into greener substitutes and new delivery systems promises to further improve health outcomes.

Looking ahead, butyl acetate faces both opportunities and headwinds. Sustainability pushes drive chemists to seek renewable raw materials, aiming for closed-loop processes that cut emissions and toxic byproducts. Tighter air quality controls steer research into low-VOC solvent blends, with butyl acetate serving as a reliable benchmark for performance and safety. Advanced coatings, flexible packaging, and next-generation adhesives apply pressure on manufacturers to tune product properties ever more precisely, forcing regular updates to purity and composition standards. New catalytic processes under development could bring down production costs and environmental impact. As automation and digital quality control become more widespread, the technical bar for both producers and users keeps rising. Each batch of butyl acetate that lands in the warehouse today reflects a legacy of invention, collaboration, and risk management stretching back a century, hinting at even more creative solutions on the horizon as needs change and new challenges arise.

Butyl acetate doesn’t get much attention in daily conversations, but it plays a behind-the-scenes role in things folks rely on every day. This clear liquid pops up most in paint cans and nail polish bottles. It helps dissolve other substances in paint, so the color stays smooth and spreads without streaks. Step into any freshly painted room, and the slightly sweet scent lingering in the air comes from butyl acetate evaporating as the paint dries.

As a solvent, butyl acetate sits high on the list for factories that make coatings. It lets paint dry at a reasonable pace—not too fast, which causes cracks, and not too slow, which traps dust. Builders, car shops, and carpenters depend on it, since dried paint forms an even coating that not only looks good but also protects the material beneath.

Cosmetic makers turn to butyl acetate for nail polish because it mixes colors well and leaves them glossy. The liquid keeps polish stable, so it won’t clump or separate in the bottle. After getting nails painted at a salon, most people notice the sharp, fruity scent that lingers through the day. That’s the butyl acetate evaporating, carrying the color and shine to the finished nail.

Factories blending cleaning products also reach for this solvent. It breaks up oil and grease, making it useful for products that need to wash away stubborn messes. Even in the world of food flavorings, butyl acetate finds a home. Chewing gum, some candy, and even artificial apple flavor often rely on tiny quantities of this compound for a sweet, smooth aroma. Strict regulatory oversight keeps these uses safe. The FDA, for example, sets tight controls on how much ends up in food, since butyl acetate in large amounts can bother the lungs or skin.

Having spent time in industrial workshops, I’ve seen folks who work with paints or solvents day in and day out reach for respirators and gloves first, long before tools. Butyl acetate’s vapors can irritate the throat and eyes. Over time, breathing in too much increases health risks. Safety rules make a big difference, so workplaces keep air flow strong and train workers to handle spills. Groups like NIOSH (the National Institute for Occupational Safety and Health) set daily exposure limits to protect people from lasting harm.

Home use matters too. Sprucing up a room with a fresh coat of paint means cracking open windows just as much as selecting a paintbrush. Labels remind users not to linger in closed spaces while paint dries. It's wise to look past the colorful branding on the can and check for ventilation advice and warnings. Choosing water-based paints, which need less butyl acetate or none at all, also helps keep indoor air easier to breathe.

Most butyl acetate still comes from fossil fuels, but that may change. Inventors and engineers look for greener ways to make it, such as using sugars from plants through fermentation. With stronger rules and changing consumer expectations, more companies are searching for alternatives or tweaking formulas to cut down on strong solvents completely.

Paint makers and chemical engineers aim to keep results the same while lowering risks. Reducing reliance on harsh chemicals requires steady research and feedback from people who use these products each day. Paying attention to safety—both at work and at home—makes a difference in the long term, not only for health but for the environment.

Butyl acetate shows up in places people don’t always expect. Factories use it to make paint, lacquers, nail polish remover, and even some artificial fruit flavors. This clear liquid often comes with a sweet smell. That pleasant scent tricks people into thinking it’s harmless. Things get complicated in real-world settings, where folks breathe in fumes or get splashes on their hands. Health risks exist, and ignoring them doesn’t help.

Most people bump into butyl acetate at work. Anyone spraying auto paint, producing varnish, or cleaning up after an art class can end up breathing the fumes or getting them on skin. Poor ventilation pushes small amounts of vapor to dangerous levels. At home, using nail polish remover in a closed bathroom raises indoor air concentrations higher than people realize. The problem doesn’t feel obvious until symptoms turn up.

Breathing butyl acetate for even a short time causes eye and throat irritation. Nose tingling, headaches, dizziness, and nausea often follow. After several hours of painting in a stuffy studio, I wound up feeling groggy and couldn’t focus. Safety data backs that experience. The Centers for Disease Control and Prevention warns that concentrations over 200 parts per million in air are enough to knock most people for a loop. High levels can cause unconsciousness. Butyl acetate can irritate skin and even cause blistering if left on too long, so gloves aren’t optional.

Chronic exposure means bigger trouble. Anyone working daily with solvents over months or years faces memory problems, lowered mood, and nerve issues. People in furniture factories sometimes mention numbness in fingers or tingling in their hands. Research links this to chemicals like butyl acetate and lack of protection. While cancer risks from butyl acetate remain unconfirmed, the short-term nerve and respiratory effects stack up when exposure goes unchecked. The World Health Organization points out that constant, unprotected contact increases chances for both skin and respiratory system problems.

Workers in paint shops, print plants, and nail salons face the highest risks. Small business owners and home hobbyists rarely have fancy fume hoods or air monitors. Kids and pets in poorly ventilated closed spaces can get sick much faster than adults. Pregnant workers need to keep their distance because exposures to many solvents, including butyl acetate, bring unknown risks to developing babies.

Basic safety steps make a difference. I started storing all paint and solvents in sealed containers and only used them near open windows. Fans pointed to the outside bring down indoor vapor quickly. Gloves and safety goggles matter more than people think. Businesses must offer proper training and regular ventilation checks. Center for Occupational Health and Safety guidelines recommend pushing for air quality tests in work areas and swapping out solvent-heavy products for safer options whenever possible.

It pays to read the label and respect any chemical, no matter the smell. People deserve to know the risks and choose protection, whether at work or at home. Butyl acetate helps paint dry smooth, but it never belongs in anyone’s lungs or left soaking through skin.

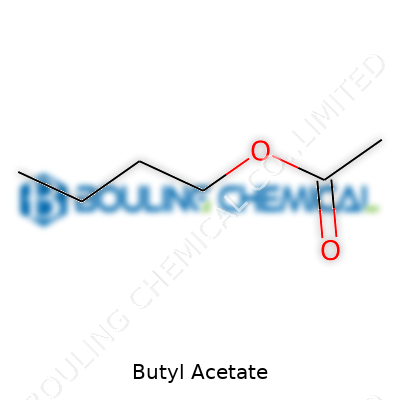

Butyl acetate’s formula is C6H12O2. I first learned this while brushing up on organic chemistry for a school project, but the numbers reach beyond a textbook. They point to something I’ve crossed paths with in everyday life, though I didn’t realize it at the time. The formula tells a small part of its story: six carbon atoms, twelve hydrogen, and two oxygen. Those simple building blocks create a colorless liquid with a fruity scent—the sort you recognize in nail polish remover, paint thinners, and even some candies.

Every time I’ve walked through a freshly painted room or opened a bottle of art supplies, butyl acetate has likely been part of that experience. Workers in paint shops and factories come across it all the time and it doesn’t just stop at industrial use. It shows up in food labs, playing a part in artificial flavors. Some apple and banana candies rely on it for that pop of aroma. It even turns up in perfumes as a blending agent. Despite its appealing smell, breathing too much for too long can irritate nose and throat, so safety guidelines aren’t just red tape.

Spending enough time in spaces using this solvent, I’ve realized what strong ventilation means to comfort. The Centers for Disease Control and Prevention points out that high levels over time could cause headaches, dizziness, or worse. That’s not a risk to brush off, especially for workers spending day after day near open containers. My time helping repaint a community center taught me the importance of open windows and proper masks—not just for myself, but for everyone joining in. Simple steps matter: reading labels, using gloves, and following fresh air rules make a big difference. Factories have to stay on top of equipment maintenance and employee training because an overlooked step leads to lasting health trouble.

Every chemical we use gets into the larger cycle. Butyl acetate isn’t the kind of threat that lingers for decades in the air or soil, but spills and sloppy disposal hurt fish and aquatic life. I once visited a river cleanup where old barrels—some possibly leaking solvents like this—reminded me that the impact doesn’t end after leaving the warehouse. The US Environmental Protection Agency recommends responsible storage and handling, and I’ve seen local governments push businesses to use safer alternatives when possible. Cleaner methods often mean higher upfront costs, but residents and workers deserve clean air and water.

Many industries still count on butyl acetate because it works. Finding safer substances or better practices takes clear information and commitment from managers right to the folks on the floor. Substitution isn’t always possible, so improved ventilation, tighter storage, and more thorough employee training should become part of the everyday routine. In schools and craft studios, teachers can pick lower-toxicity products and teach students about proper handling. Science and industry move forward when those closest to the tools have the right resources and support. Even a well-known solvent like butyl acetate deserves regular attention, because safety and health shape daily life, not just science labs.

Anybody who has ever picked up a paintbrush owes a subtle thank you to butyl acetate. This solvent brings the smooth, even texture painters count on. Companies making automotive finishes, home paints, and industrial coatings use it in huge volumes, letting pigments and chemicals blend without stubborn lumps. Spray paint lays down better, dries in good time, and holds up longer on walls and metal. Most of us expect the color on our cars and house walls to look sharp for years, and much of that resilience starts with how the paint goes on. Butyl acetate is a quiet enabler of this process.

Breathing room is essential on job sites. Paints with butyl acetate give off less choking odor than older formulas and help crews get back to work quicker. Less time spent dodging fumes is good for everyone.

Walk into a major print shop and you’ll find butyl acetate behind the rich color on magazines, cereal boxes, and glossy flyers. Solvents carry the dyes and pigments evenly across complicated machines, allowing sharp edges and quick drying. If the ink dries too slowly, pages stick together, leading to costly jams and delays. Printer operators depend on butyl acetate to keep the runs flowing, especially in packaging where quick turnaround makes or breaks a business.

Even small print runs benefit. I've helped friends with side hustles in sign-making, where consistency matters as much for a handful of posters as it does for a run of 10,000.

Sealing cracks in windows or joining soles to shoes isn’t possible with water alone. Butyl acetate belongs in the toolkit of adhesive manufacturers who need glues to set strong and clear, without a sticky, lingering film. Shoe repairs, auto gaskets, and building joints—all exploit how quickly and cleanly this solvent works. It helps the glue spread and then vanish during curing, leaving behind a reliable bond.

Years ago, I patched the sole of a favorite boot using strong adhesive with butyl acetate in the mix. That patch outlasted the rest of the boot. Factory assembly lines rely on the same effect every single day.

Most folks don’t realize perfume makers often turn to butyl acetate to develop scents with staying power. It helps dissolve essential oils and fixatives, mixing everything smoothly so that every spritz smells the same from bottle to bottle. Nail polish is another big user, giving both gloss and durability while letting the lacquer glide onto fingernails without streaks or drags. Stylists demand a polish that holds up under salon lamps and butyl acetate delivers.

Some jobs demand heavy-duty cleaning. Industrial shops use butyl acetate to remove leftover inks from presses, degrease machinery, and prepare surfaces for treatment. As an alternative to harsher chemicals, it cleans up without as much threat to workers’ lungs and skin. Companies increasingly look for tough solvents that also keep health concerns in check, and this one stands out.

Cleaner equipment leads to less downtime and longer lifespans for expensive machines, a fact any shop manager learns quickly.

Not all solvents treat health and safety kindly, and butyl acetate brings fewer risks than some others on the market. Companies that value worker safety set up ventilation and keep exposure low, even with a friendlier compound. Manufacturers continue developing greener, safer alternatives, but for now, butyl acetate still serves as a backbone in everything from painting a city bus to bottling perfume.

Knowledge and vigilance are the keys. Proper training, better air systems, and ongoing research into new ingredients protect people and the planet, letting the industries that rely on butyl acetate keep running strong while looking ahead to improvements.

Butyl acetate, clear and sweet-smelling, pops up in everything from nail polish to paint thinners. It is part of daily life for folks working in labs, garages, factories—even some artists run into it. This isn’t the sort of chemical that hides in the background. Mistakes here bring real trouble, not just regulatory headaches but health problems you might not see coming.

Anyone storing butyl acetate quickly learns that it won't forgive shortcuts. This liquid evaporates fast, and the fumes can make you dizzy in minutes. Forgetting to close a cap, ignoring a tiny leak, or missing one worn gasket on a storage drum—all invite fire and health hazards. One spark, even from a static charge, could light up a workplace. In my own hometown, an auto shop burned badly a few years back because a worker knocked over a container and didn’t bother reporting it. Fire moved faster than anyone thought possible.

The rules sound basic for good reason. Stainless steel or tightly-sealed, compatible plastic storage bins keep butyl acetate contained and safe. You stick them in cool, dry, well-ventilated spaces away from heaters, sunlight, or any sparks. Fire codes put these spaces far from electrical panels and open flames, and not just for show. Fires that start with vapors often end up larger than people can manage with an extinguisher.

Good labeling, double-checking seals, and keeping records of how much product moves in and out matter more than folks realize. I’ve watched warehouses ban open flames and install explosion-proof lighting only after close calls. It’s always better to think through what could go wrong before getting surprised by it.

Training comes from more than a quick briefing. New hires, especially those right out of school, may have only worked in classroom settings. Real-world storage and transfer bring surprises—dripping drums, faulty pumps, moving barrels on rainy days. Companies with low injury rates hold hands-on drills. They put spill kits in the open, not hidden away. Eye-wash stations and safety showers don’t become decorations. Gloves, goggles, and respirators fit every hand and face because management steps up to make sure the equipment is available and fits right.

Laws do their part, but nothing beats insight from the people who use the product daily. Yet ignoring outside expertise doesn’t end well. I’ve seen factory floors where only after an OSHA consultant visits does the team replace rusty shelving or install automatic shutoffs. There’s wisdom in talking to chemical manufacturers and local fire departments—especially before emergencies happen.

Butyl acetate doesn’t need to scare anyone off, but it deserves respect every step of the way. This isn't about red tape, but about going home safe after a day’s work. Reliable storage, clear routines, and speaking up quickly about spills or strange smells keep people healthy and businesses running smoothly. Proper handling safeguards people’s lives, reputations, and, not least, the everyday tools and products everyone uses without a second thought.

| Names | |

| Preferred IUPAC name | butyl ethanoate |

| Other names |

Acetic acid butyl ester

n-Butyl acetate Butyl ethanoate 1-Butyl acetate |

| Pronunciation | /ˈbjuːtɪl əˈsiːteɪt/ |

| Identifiers | |

| CAS Number | 123-86-4 |

| Beilstein Reference | 635873 |

| ChEBI | CHEBI:31328 |

| ChEMBL | CHEMBL14000 |

| ChemSpider | 5297 |

| DrugBank | DB02197 |

| ECHA InfoCard | 100.112.311 |

| EC Number | 204-658-1 |

| Gmelin Reference | Gm. 4043 |

| KEGG | C00988 |

| MeSH | D001973 |

| PubChem CID | 31272 |

| RTECS number | AF7350000 |

| UNII | NF94B16QVR |

| UN number | 1123 |

| CompTox Dashboard (EPA) | DTXSID6020201 |

| Properties | |

| Chemical formula | C6H12O2 |

| Molar mass | 116.16 g/mol |

| Appearance | Colorless transparent liquid with a fruity odor |

| Odor | Fruity |

| Density | 0.882 g/cm³ |

| Solubility in water | 0.68 g/100 mL (20 °C) |

| log P | 1.78 |

| Vapor pressure | 11.5 mmHg @ 20°C |

| Acidity (pKa) | pKa ≈ 25 |

| Basicity (pKb) | pKb ≈ 15 |

| Magnetic susceptibility (χ) | -8.76×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.394 |

| Viscosity | 0.74 mPa·s (at 25°C) |

| Dipole moment | 1.84 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 274.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −486.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2678 kJ/mol |

| Pharmacology | |

| ATC code | V04CX10 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P403+P235, P501 |

| NFPA 704 (fire diamond) | '2-3-1' |

| Flash point | 27 °C |

| Autoignition temperature | 421 °C |

| Explosive limits | 1.7–8.0% |

| Lethal dose or concentration | LD50 oral rat 10,768 mg/kg |

| LD50 (median dose) | LD50 (median dose): 10,760 mg/kg (rat, oral) |

| NIOSH | RQ2450000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Butyl Acetate is "150 ppm (parts per million)". |

| REL (Recommended) | 150 ppm |

| IDLH (Immediate danger) | 1,700 ppm |

| Related compounds | |

| Related compounds |

Isobutyl acetate

Ethyl acetate Propyl acetate Methyl acetate n-Butanol Acetic acid |